US Customs Exams:

If you’re shipping cargo into the United States, one of the last things you want to hear is that your freight has been selected for a Customs Exam. It’s the supply chain’s version of a pop quiz, and no matter how ready you think you might be, you still get that sinking feeling in the pit of your stomach when you get the news. Even if you’re sure that you, your freight forwarder and your supplier have done everything right, you know your freight is going to be delayed and there will certainly be extra fees involved.

How long your shipment is delayed depends entirely on the type of exam you’ve been selected for, and how long it takes your cargo to get into and out of a Centralized Examination Station (CES) for inspection.

In this article we are going to take a look at the process involved in cargo inspections, the types of exams your freight may be selected for, and what is involved with each of them.

Customs and Border Protection:

The important thing to keep in mind here is that while the unexpected selection of your cargo for examination may be a huge pain in the neck for you and your final customers, it is ultimately being done with everyone’s best interests in mind. After September 11, 2001 border security became a top priority.

Overnight, our focus shifted from illegal contraband being smuggled into the country to potential weapons of mass destruction sitting in our ports on the doorstep of the largest metropolitan areas in the country. On March 1, 2003 in order to streamline cooperation and communication between a number of government agencies dealing with border security, the Department of Homeland Security combined former stand-alone agencies such as Border Patrol, Immigration and Naturalization Service, the Department of Agriculture and U.S. Customs into the Customs and Border Protection (CBP) agency.

The Process:

CBP is entrusted to select the cargo for examination using various methods and selection criteria. Nobody knows the exact methodology used to determine who gets selected and who doesn’t, and only 3-5% of the cargo coming into the U.S. gets picked for examination. Because the containers that actually get checked represent a small percentage of the total goods coming into the U.S., the CBP tries to be more focused on the cargo that represents a higher risk or possibility of an issue.

Some of these factors could range from agricultural products from a certain part of the world, tips that come in on contraband or counterfeits, new importers without a track record, questionable points of origin that are lacking in good security procedures, or companies with less than stellar track records were involved with the shipment. Sometimes, it’s just a bad luck of the draw.

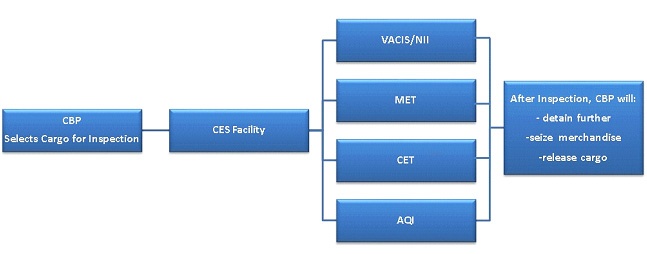

So, what does the process look like once you’ve been flagged? The simplest explanation of the process used to inspect cargo coming into the ports is this:

CBP selects the cargo > It goes to a CES facility > CBP performs an examination > It gets released, or it is held for further inspection, possibly seized, or exported back

Centralized Examination Station:

A CES is a privately owned and operated facility where the cargo is taken for examination by CBP personnel. The CES can provide transportation to their facility from the port of Container Freight Station (CFS) at the request of the Steamship line, importer, or importer’s agent.

The CES location helps facilitate the examination process by providing the CBP with a facility and a means to transport the cargo to the facility in a timely fashion. Theoretically, this will help the CBP clear a higher volume of cargo, but much of that depends on the CES provider. CES providers are typically pre-existing warehouse and trucking companies that have added to their service offerings by providing CES services. Just as you would think about cost and service with any provider in the supply chain, your choice of a CES provider should be handled in a similar fashion. Some of the questions you should be thinking about when you select a CES provider (and usually there are only a few locations per port), are:

• What inspections services do they offer. Not every CES locations will offer all four primary inspection types, and some have better reputations for timely turnaround for different inspection types.

• How many trucks is the CES operating? After all, more trucks means more capacity to pick the loads up, which means less delay in getting the product to the CES.

• How many doors are available for CBP inspection? Similar to the trucks, if there are more doors for use by CBP, more loads can be examined, and your freight spends less time at the CES facility waiting to be backed into a door.

• How much is this going to cost me?

I can’t speak for the set-up at every port, but as an example, if you look at the Port of NY and NJ, some of this information is available right online at the Port Authority website. Clicking on the link https://www.panynj.gov/port/centralized-examination- stations.html allows you to see what services are offered by each provider, and clicking on the provider name pulls up their pricing. In this case, you can see from that list that SalSon Logistics specializes in the AQI inspection, and our rates are clearly listed. If you click on the link https://www.panynj.gov/port/pdf/salson- ces-rates-2012.pdf, the rates comes up for the various types of services. What you won’t be able to tell without doing a little research is that we allocate 60 of our 200 doors at SalSon to the AQI inspection process, and that we operate 200 company owned trucks and drivers that move freight into and out of the ports on a daily basis in NJ. That’s more than twice the power and twice door space allocated for AQI coming off the Ports here in NJ, compared to the competition.

Types of Exams:

VACIS/NII: VACIS stands for Vehicle and Cargo Inspection Systems, and is also commonly known as NII or Non-Intrusive Inspection. This type of exam is similar to scanning your luggage at the airport, and it involves a giant X-Ray machine that uses gamma ray technology to take a non-intrusive look at the contents of the freight container.

Of course in this case, the government isn’t looking for water bottles or toiletries with over 3oz of fluid, they are looking for drugs, weapons, illegal immigrants, and even currency. In this type of exam, the seal is not broken (unless the scan warrants a closer look), and the container can be on its way fairly quickly once it is examined. You will have to pay for the transport of the container to the VACIS facility and the exam, and the container will not be released until those charges are settled.

Trade Compliance/MET (Merchandise Examination Team): In this type of exam, the CBP officials examine invoices and packing lists on a random basis looking for a couple of different things. The most common problems surround the under-invoicing of the true value of the goods on the invoice in order to lower the duties/taxes that need to be paid. Other times CBP officials are looking at the goods to determine if they comply with copyright and licensing agreements. In other words, they are checking to see if any of the products are counterfeit.

Anti-Terrorism Contraband Enforcement Team (AT- CET): This is probably the most intensive type of exam that is performed on Cargo. This requires the cargo to move to a CES on a bonded carrier, where it will sit in queue for an undetermined amount of time (usually several days depending on the backlog). Eventually everything will have to be unloaded and inspected, and a thorough search of all the freight begins.

Usually these types of inspections are triggered by a suspicious VACIS or NII exam. Again, going back to the airport analogy (because we’ve all gone through those), it’s the equivalent of the x-ray machine seeing something in your bag that shouldn’t be there, and you get pulled out of line for a physical search of your belongings. However, with a cargo container it’s usually not as quick or painless as dumping out a water bottle, or leaving behind the jumbo sized bottle of shampoo.

CET inspections usually involve some pretty hefty fees, plus demurrage charges from the steamship lines for the containers being tied up for so long.

Agricultural Quarantine Inspection (AQI): The AQI program plays a critical role in facilitating the safe trade of agricultural commodities while protecting U.S. agriculture and the environment from invasive plant and animal pests and diseases. As volumes of international trade and travel both increase, so do the risks that foreign animal and plant pests and diseases can enter and establish themselves in the United States. These invasive pests and diseases can pose grave threats to America’s agriculture and economy.

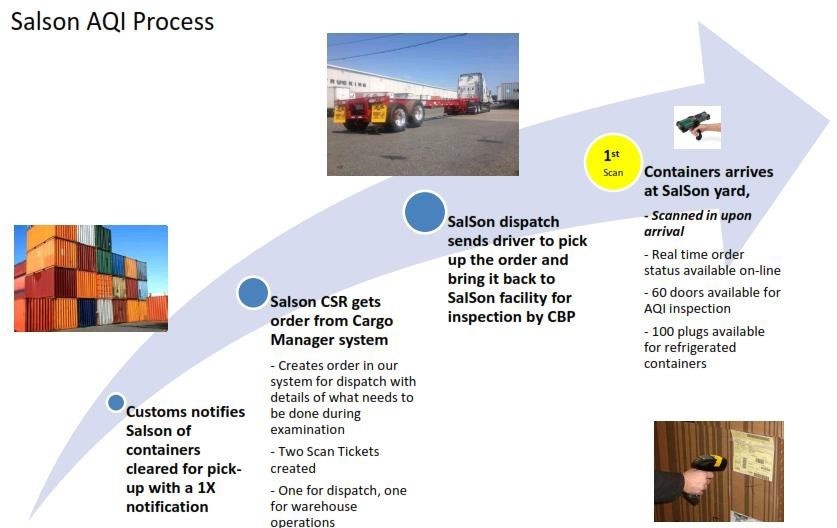

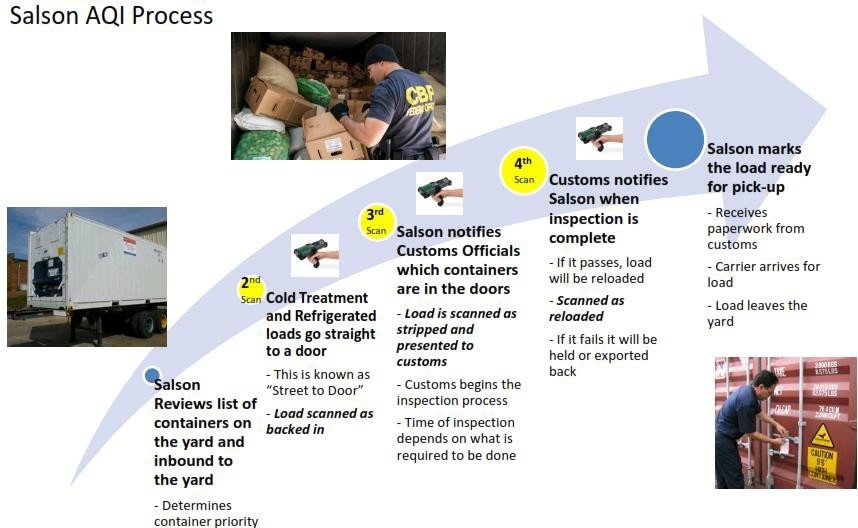

At the SalSon CES facility, we specialize in AQI inspections. With US Customs and Border Patrol staff stationed at our facility, 60 doors dedicated to cold chain, refrigerated and dry AQI inspections, 200 drivers moving in and out of the NJ ports on a daily basis, and located 1 mile from the port in a 24/7 secured facility, we offer many advantages over our competitors in AQI inspection.

SalSon also offers a 4 point scanning process of the containers that come into the CES for inspection. The customer/importer will know every major step in the process that the cargo is going through.

We understand:

• No customer likes having their cargo selected for exam

• Customers/Importers hate the lack of visibility during the process

• It may not be the steamship line’s fault, the forwarder’s fault, or the Central Examination Station’s fault for the selection, but it becomes all of our problems when there is an upset customer involved

• We offer visibility in the CES/AQI process to soften the blow as much as possible by giving the customer information and insight regarding their cargo.

What Can You Do To Minimize The Impact Of Cargo Inspections To Your Supply Chain?:

As in most cases, prevention is usually the best cure. Avoiding a cargo inspection in the first place is the best way to reduce the impacts on your supply chain. While there is no sure fire approach to do this, you can start by doing some simple things:

• Use reliable partners at every step in the supply chain. Anyone that’s involved in the process who has a shady reputation can get your cargo flagged.

• Get your documents in early so your forwarder or customs broker can file your paperwork without delay. In addition:

• Make sure you have good descriptions of what you’re shipping

• Make sure your valuations are good

• Consider your country of origin, and try to avoid high risk countries

• Get to know your CBP folks. They aren’t the enemy, they’re doing their best to protect us from weapons, counterfeit goods, contraband, and terrorist threats. Helping them get to know you and your company could help smooth out the process.

If all else fails, and your cargo gets selected, makesure your CES partner has their act together. Let’s faceit, having your cargo selected for examination isnever going to be your first choice, but partnering with aCES provider that can streamline and give you visibilityto the process will at least alleviate some of theheartburn.

About SalSon:

SalSon Logistics is an asset based third party logistics company providing comprehensive supply chain management solutions that span the globe. Our supply chain management solutions are flexible, scalable, and offer visibility throughout the supply chain.

SalSon offers services that range from port drayage, regional and local deliveries, CES and CFS services, warehousing, foreign trade zone, retail pool distribution and Dedicated Contract Carriage.

SalSon employs more than 1,200 associates and operates more than 1 million square feet of warehouse space . SalSon is an asset based provider with a fleet of 550 tractors and 1,500 trailers.